MANUFACTURER:

CherkasyElevatorMash Ltd TM BRONTO

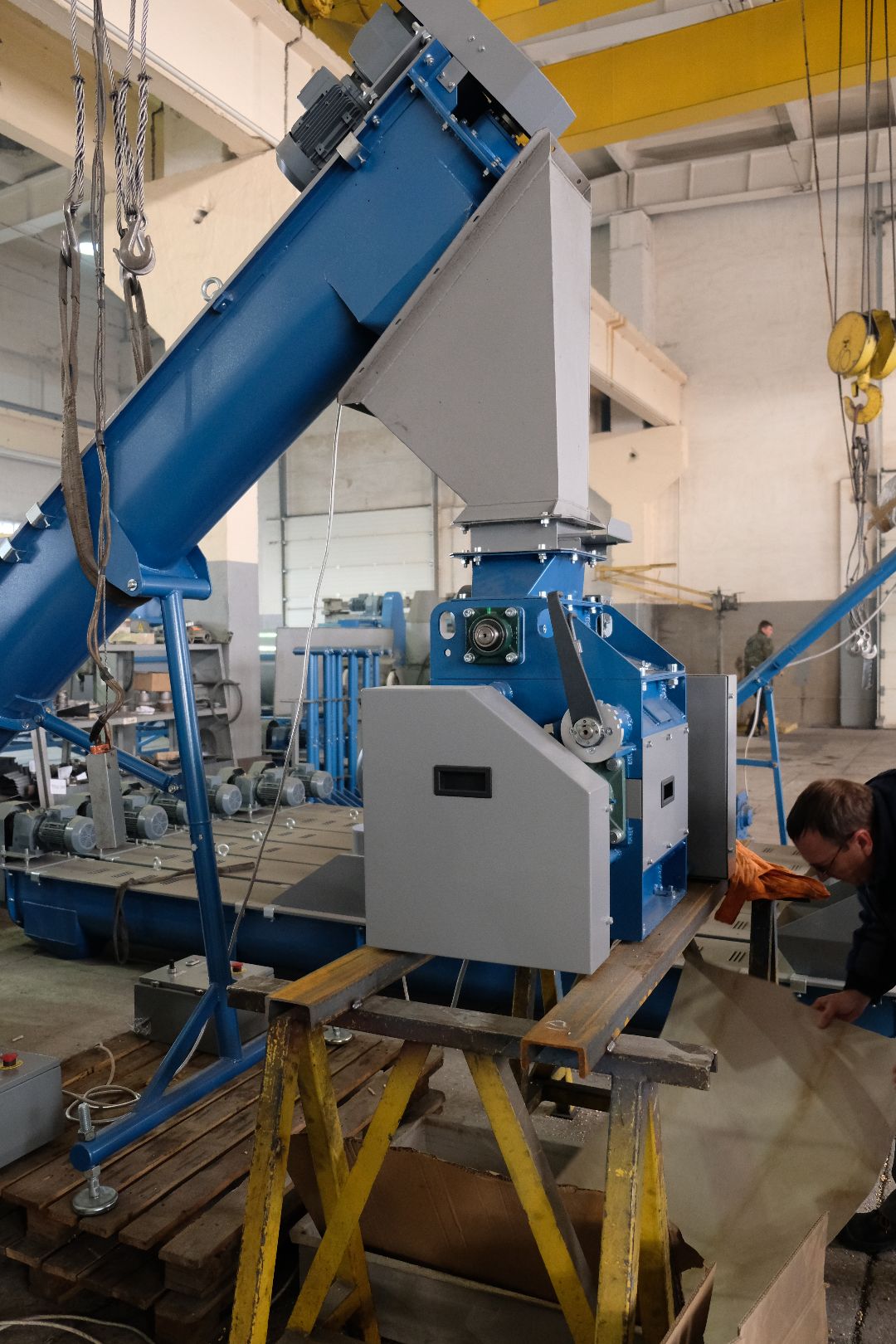

Grinding raw materials between two rolls.

CherkasyElevatorMash Ltd TM BRONTO

• for grinding grain, oilseeds and

legumes between two rolls

Watch how ROLLER MILL operates:

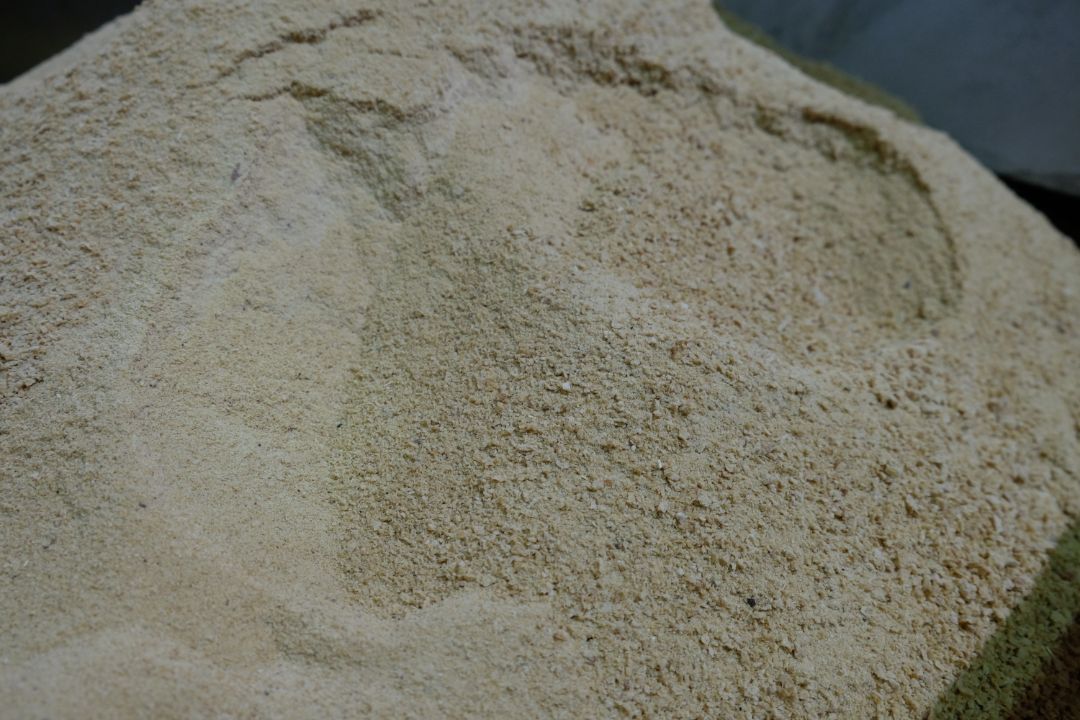

PRODUCT: MILLED GRAIN, BEAN AND OIL CROPS

(fraction 3 ... 8 mm)

RAW MATERIALS: CEREALS, BEANS AND OIL CROPS

(humidity: max 10%)

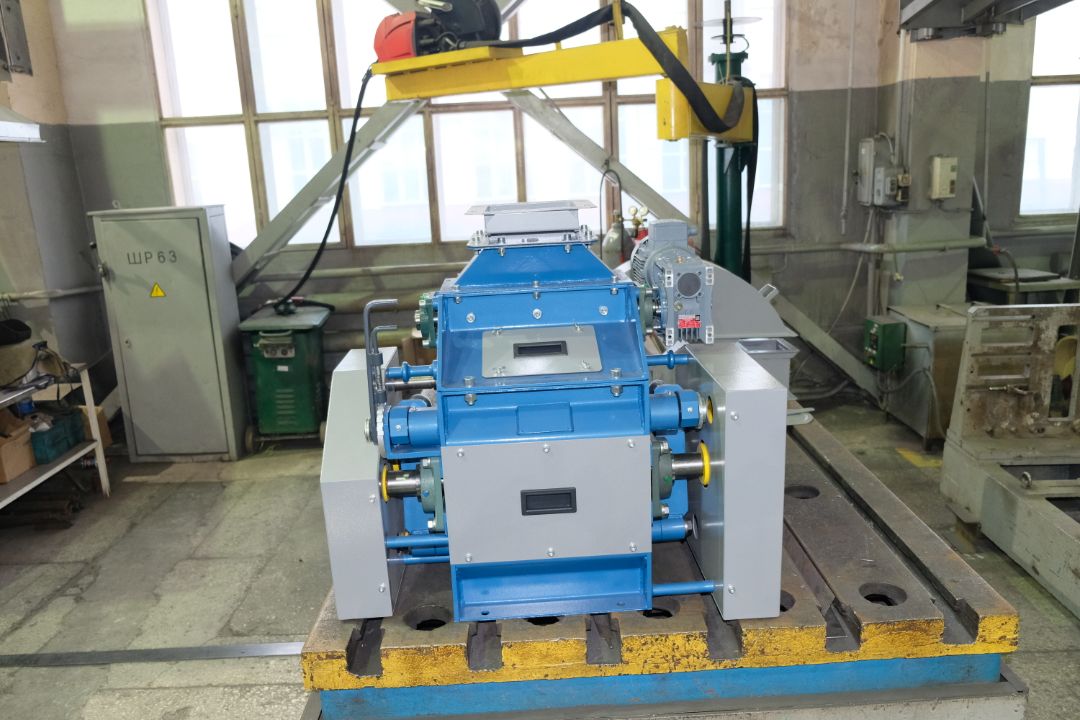

SPECIFICATIONS:

Productivity: max 2000 kg / h

Bulk weight of raw materials: mіn 700 kg / m³

Humidity of the feedstock: 7 ... 10%

Length: 1025 mm

Width: 950 mm

Height: 875 mm

Weight: 520 kg

POWER: 6.25 kW

Feeder turns - are set and supported from the control panel.

The rolls are protected against ingress of solid and metal objects.

ADVANTAGES:

• crusher gate feeder speed - adjustable

• the gap between the rolls - adjustable during operation

• can be used as an independent technological unit

• can be used in technological lines

ROLLER MILL OPERATION SEQUENCE:

• Raw materials are fed into the hopper above the crusher

• The gateway feeder shaft rotates at a variable speed

• Raw material moves from the hopper to the crushing zone

• Rolls rotate towards each other

• The grain falls into the gap between the rolls (adjustable) and is split by the notches of the rolls

• The crushed product pours out from the bottom of the roller crusher

Quality assurance:

Warranty period is 1 year

• all machines are certified according to ISO 9001: 2015

• our extruders are designed for continuous and trouble-free operation