MANUFACTURER:

CherkasyElevatorMash Ltd TM BRONTO

To remove the seed fiber.

About LSG-4 peeler:

CherkasyElevatorMash Ltd TM BRONTO

VIDEO WITH PEELER:

FINAL PRODUCT:

RAW MATERIALS:

TECHNICAL SPECIFICATIONS:

Productivity: max 4000 kg / h

Humidity of raw materials: 7 ... 10%

The remainder of the husk in the product (from the initial): max 1,5%

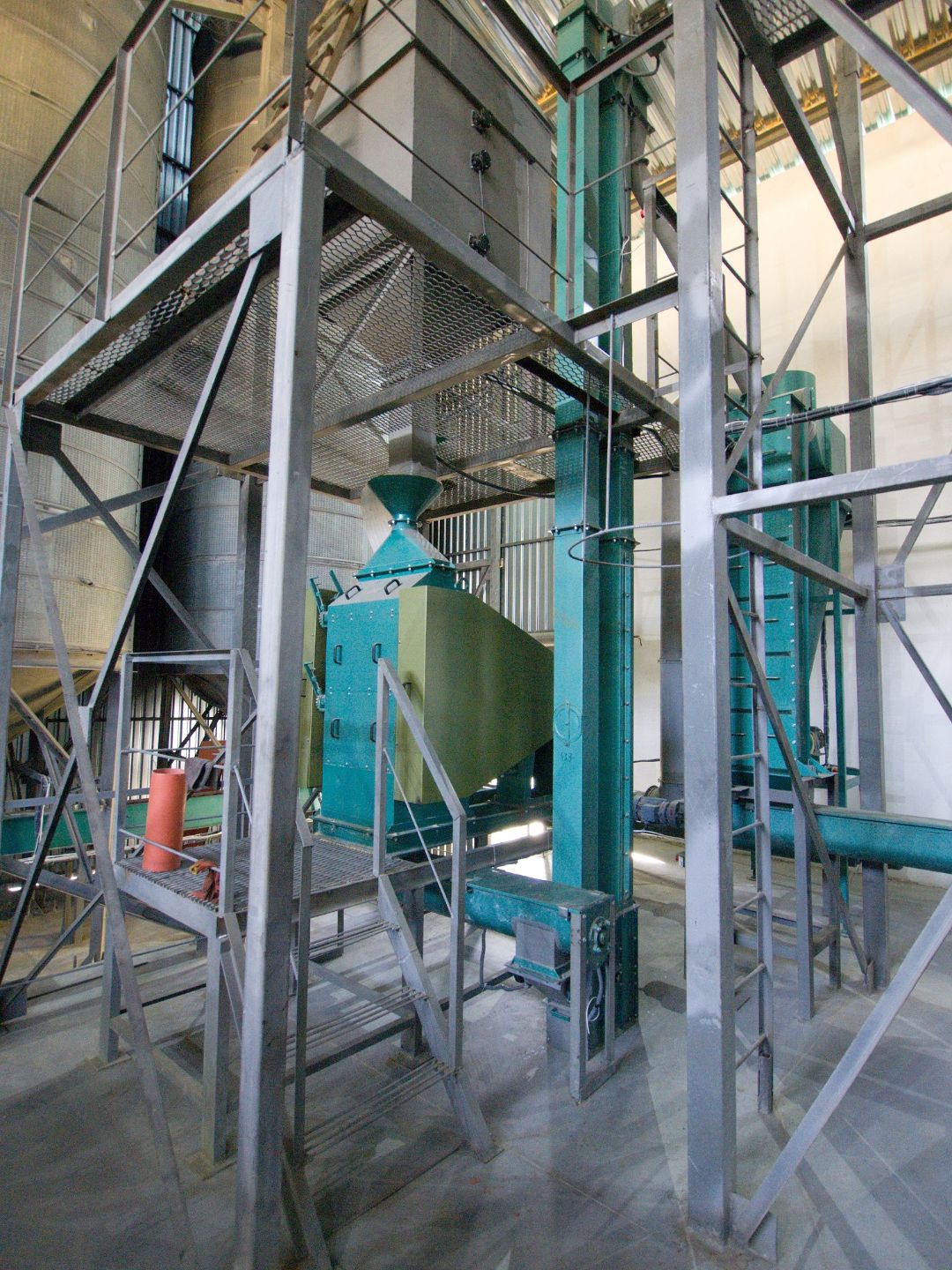

Length: 6000 mm

Width: 2400 mm

Height: 5500 mm

Weight: 4000 kg

POWER: 24 kW

ADVANTAGES:

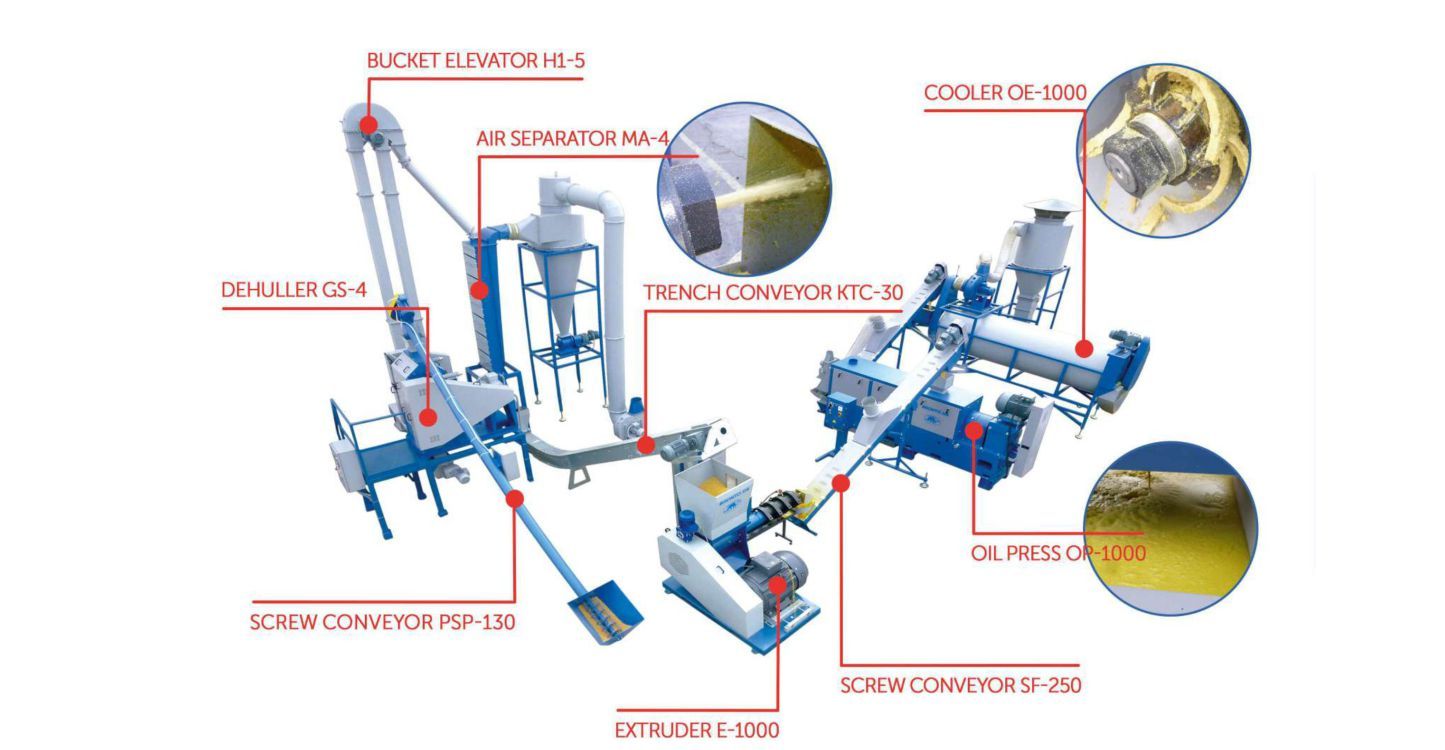

SEQUENCE OF EXTRUDER OPERATION:

Quality assurance:

Warranty period is 1 year