MANUFACTURER:

CherkasyElevatorMash Ltd TM BRONTO

To reduce the oil content of raw materials from 25 to 8%.

CherkasyElevatorMash Ltd TM BRONTO

VIDEO WITH SOYBEAN OIL PRESS:

FINAL PRODUCT:

RAW MATERIALS: soybean, soybean kernel

preheat to 90 ... 110 ° C

TECHNICAL SPECIFICATIONS:

Productivity: max 1000 kg / h

Humidity of the raw material: 7 ... 10%

Oilcake of oilcake: 7 ... 9%

Oil yield: max 18%

Length: 4200 mm

Width: 1100 mm

Height: 1200 mm

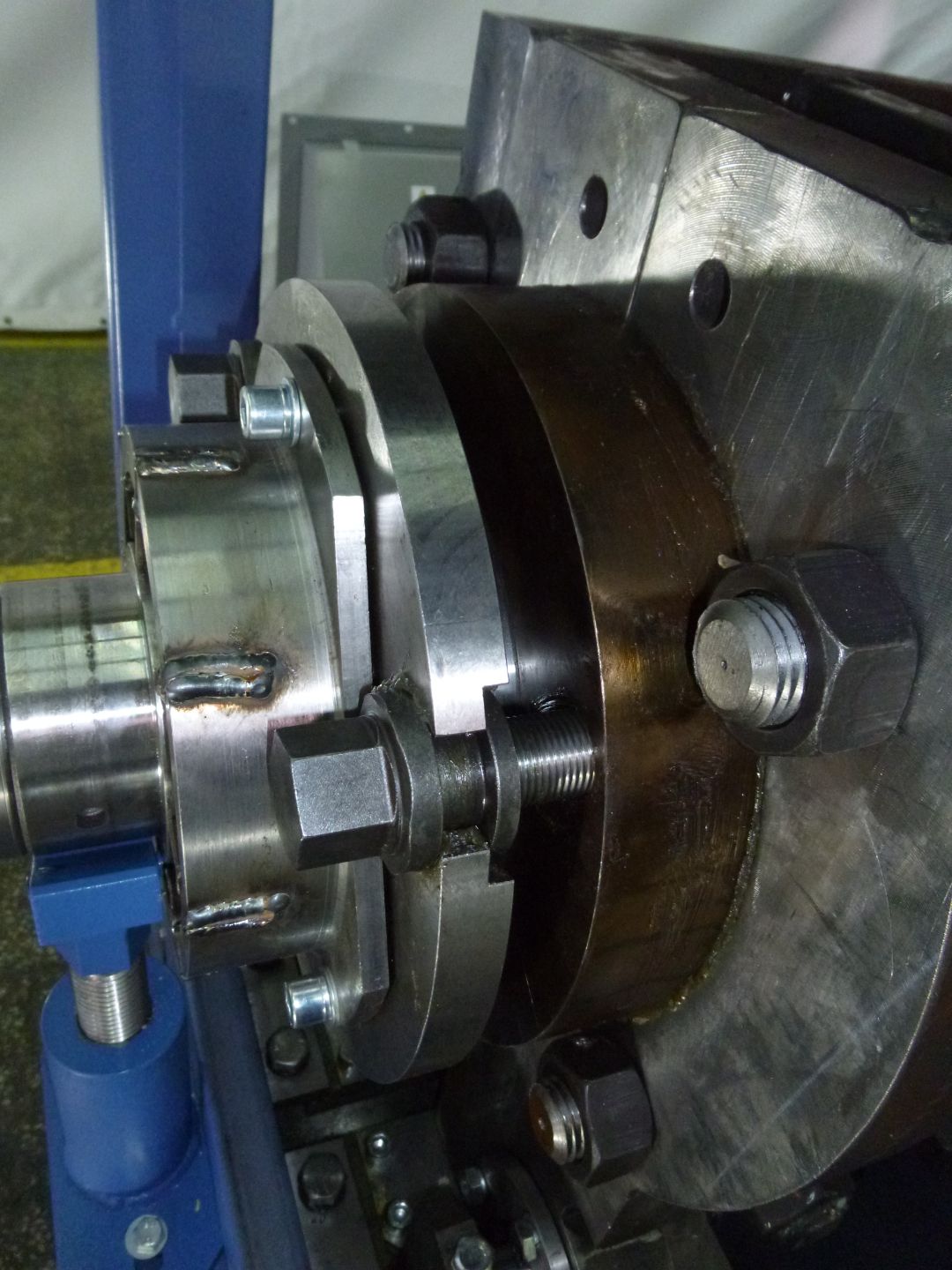

Weight: 3500 kg

POWER: 22 kW

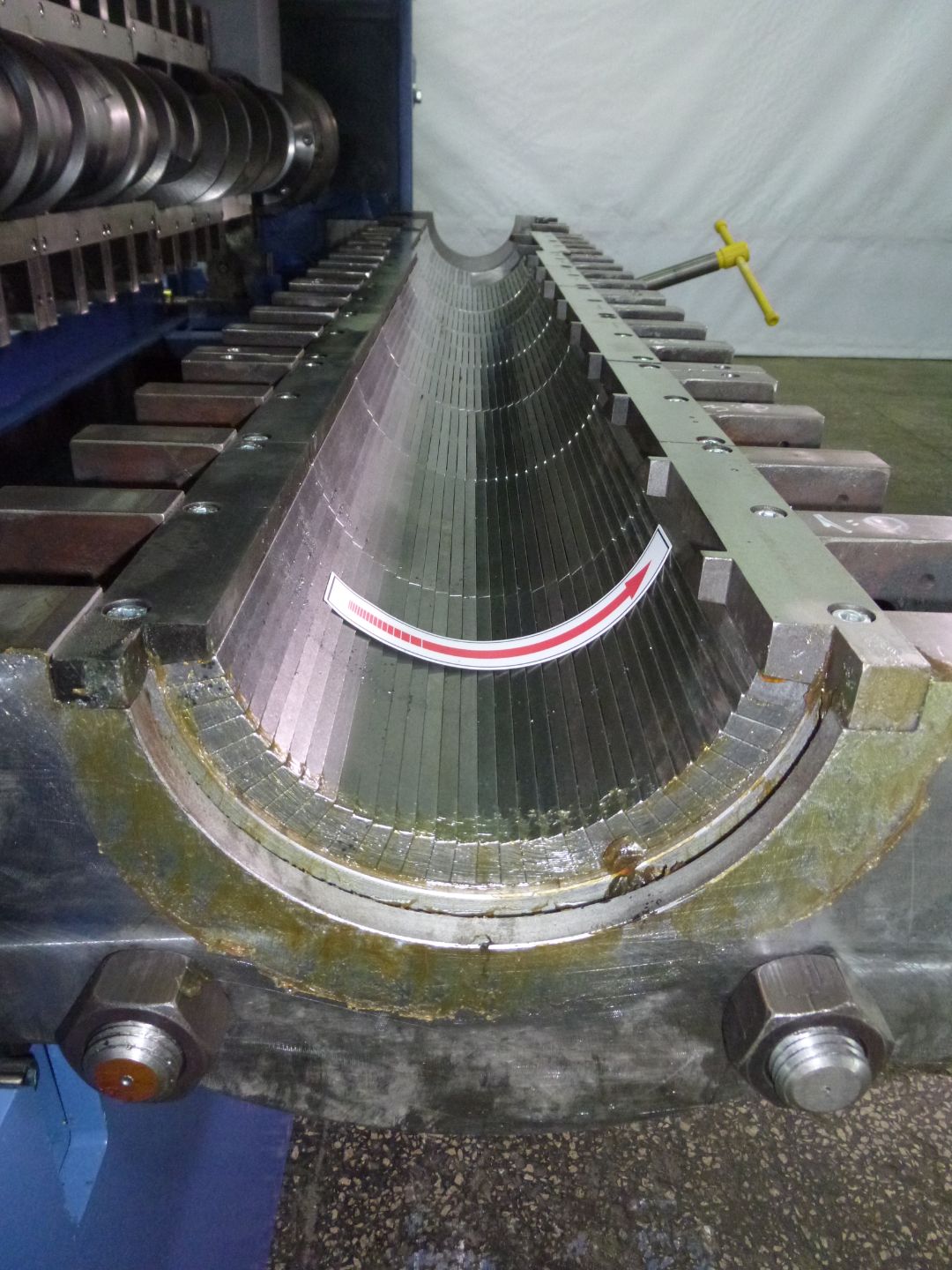

Resistance to wear parts of the grain chamber:

min 5000 tons

ADVANTAGES:

SEQUENCE OF SOYBEAN OIL PRESS OPERATION:

Quality assurance:

Warranty period is 1 year

We produce the OP-1000 soybean oil press in series.