MANUFACTURER:

CherkasyElevatorMash Ltd TM BRONTO

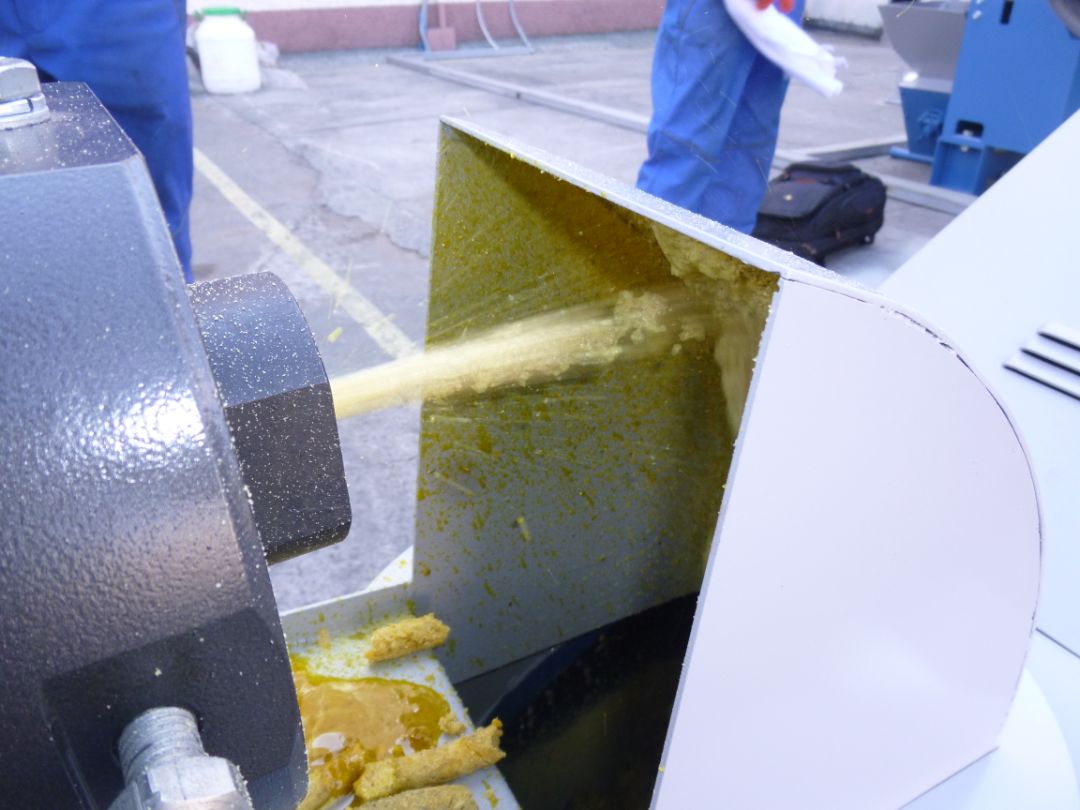

Extrusion with humidity up to 12%.

CherkasyElevatorMash Ltd TM BRONTO

VIDEO WITH EXTRUDER:

FINAL PRODUCT: Full-fat soya, full-fat rape

RAW MATERIALS: soybean, soybean kernel, rapeseed

humidity: 8 ... 12%

TECHNICAL SPECIFICATIONS:

Productivity: max 1000 kg / h

Raw material humidity: 7 ... 16%

Length: 1800 mm

Width (with divider): 2600 mm

Height: 1900 mm

Weight: 2500 kg

POWER: 92 kW

The raw material is processed in the extruder for no more than 30 seconds.

Therefore, both proteins and fats in soybeans retain their nutritional qualities.

ADVANTAGES:

SEQUENCE OF EXTRUDER OPERATION:

Quality assurance:

Warranty period is 1 year

More than 1 500 E-1000 extruders have been mass-produced