MANUFACTURER:

CherkasyElevatorMash Ltd TM BRONTO

CherkasyElevatorMash Ltd TM BRONTO

• production of high protein feed component

• production of vegetable oil

• soybeans, peeled soybeans 24 t/day

• SOYBEAN OIL

• SOYBEAN PRESSED CAKE (oil content 7 ... 8%)

(urease: 0.05 ... 0.2 pH)

• power line (workshop): min 160 kW

• production area:

min 200 m²

• storage area of raw materials: min 250 m²

• floor storage area for oil cake: min 300 m²

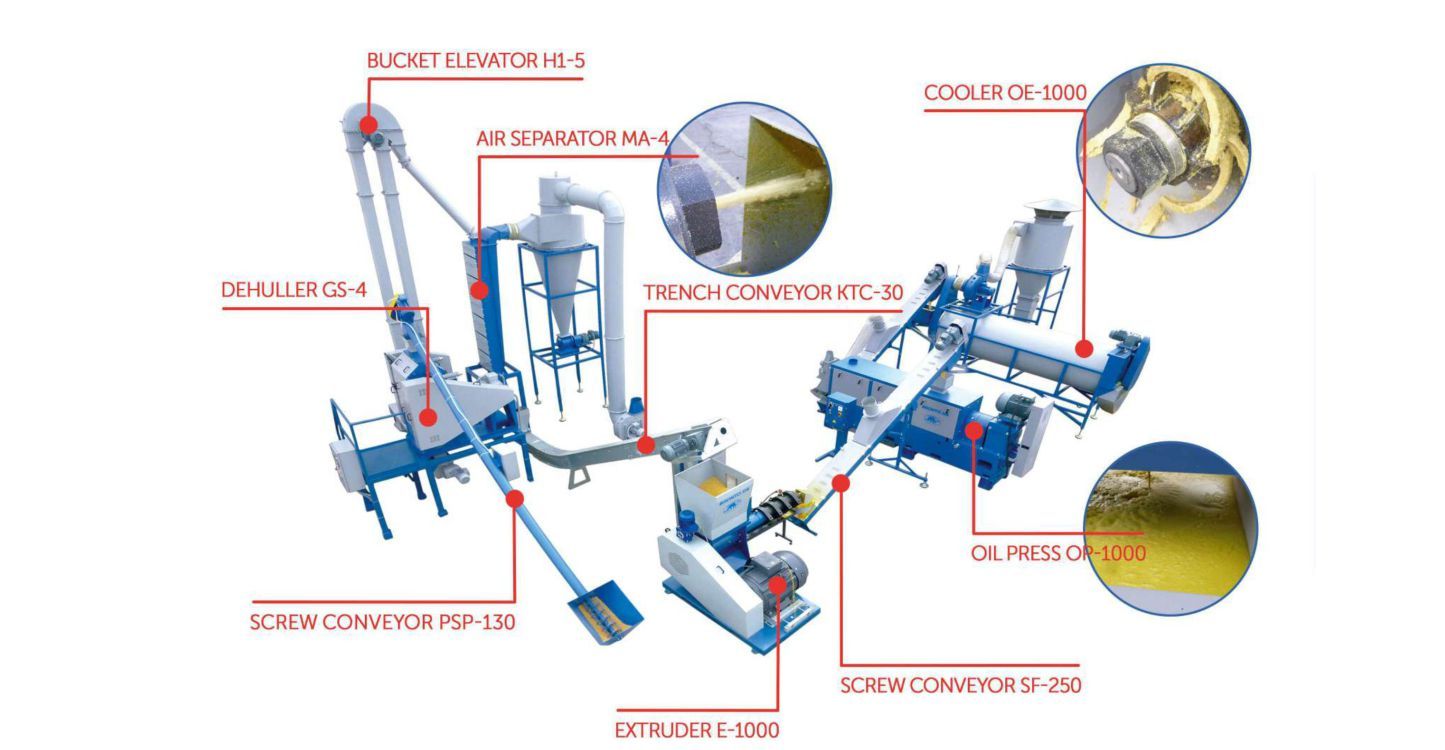

SOYBEAN OIL PLANT:

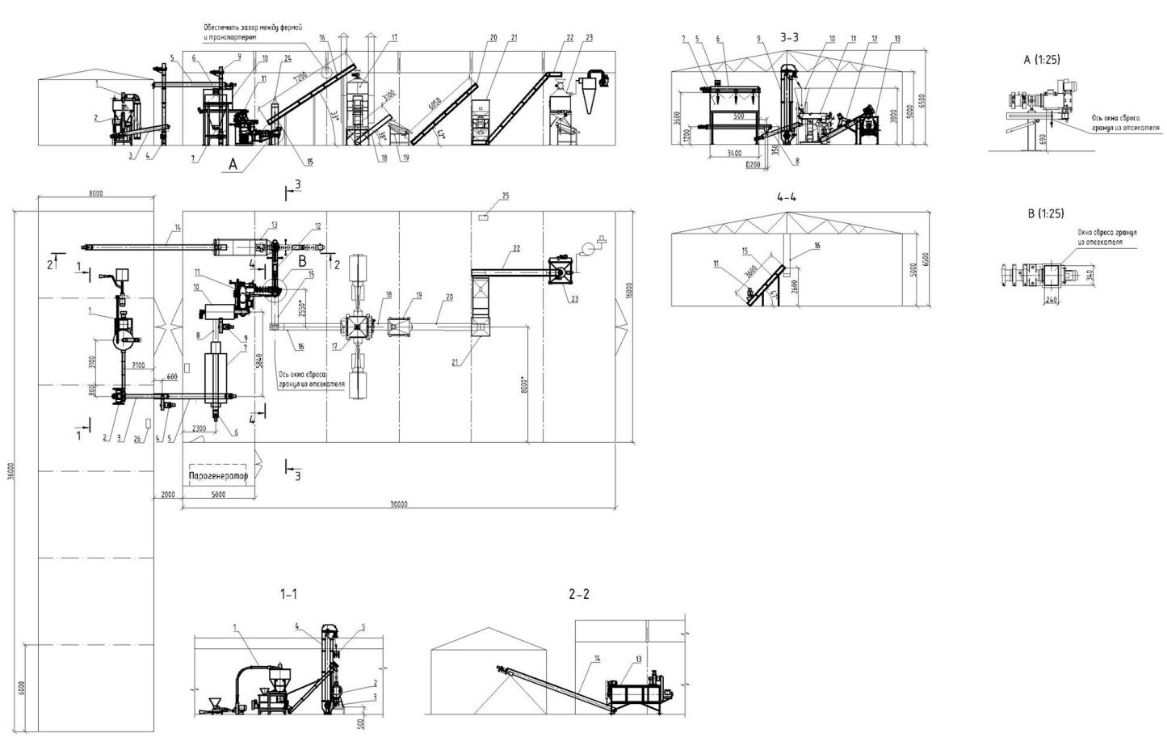

EXAMPLE OF LAYOUT DESIGN:

HOW SOYBEAN OIL PLANT OPERATES:

Warehouse: from 250 m²

Raw material cleaning: storage standards

Dosing of raw materials: up to 8 ... 10%

Fiber removal: up to 5% by weight of raw materials

Increase in protein specific gravity in oil cake: by 2 ... 3%

Raw material heating: 120 ... 150 °C

Decrease in urease activity: up to 0.05 ... 0.2 pH

Moisture decrease: by 1 ... 3%

Oil cake production:

• protein: 40 ... 48%

• oil content: up to 8%

Oil production:

solids residue content: up to 3%

Decrease in temperature:

after the final product had been discharged from the cooler, its temperature is 5 ...10°C higher than the temperature in the shop

Impurity reduction: removal of up to 90% of impurities

Floor storage warehouse: from 300 m²

Storage capacity: from 70 m³

Determination of fat and protein content, moisture, urease activity

DESCRIPTION OF TECHNOLOGY: